Beyond the Plans: Unveiling Hidden Gems in Wooden Boat Building

How to Make a Wooden Boat for Fun and Outdoor Adventures, while a valuable resource for aspiring boat builders, often skims over nuanced aspects crucial for success. This review delves beyond the standard instructions, exploring often-overlooked elements with a focus on innovative approaches and fresh perspectives.

The Unsung Heroes of Boatbuilding: Material Selection and Sustainability

Most guides focus on *what* wood to use, but rarely delve into the *why* and the impact of choices. This is a missed opportunity. Let's explore this further.

Q: Beyond the typical cedar and mahogany, what sustainable and readily available alternatives can hobbyists consider?

A: The answer lies in exploring locally sourced reclaimed wood. Think beyond the lumberyard. Demolition sites, old barns, and even responsibly managed forests offer unique wood types with distinct character. Consider Paulownia, known for its lightweight strength, or even sustainably harvested bamboo for a truly unique and eco-conscious build. Researching regional lumber availability is crucial, reducing transportation emissions and supporting local economies (see: Sustainable Forestry Initiative guidelines and your local forestry commission). This not only reduces environmental impact but offers a fantastic opportunity for creative design, incorporating salvaged wood's unique patterns and textures.

Q: How can I minimize waste and maximize resource utilization during construction?

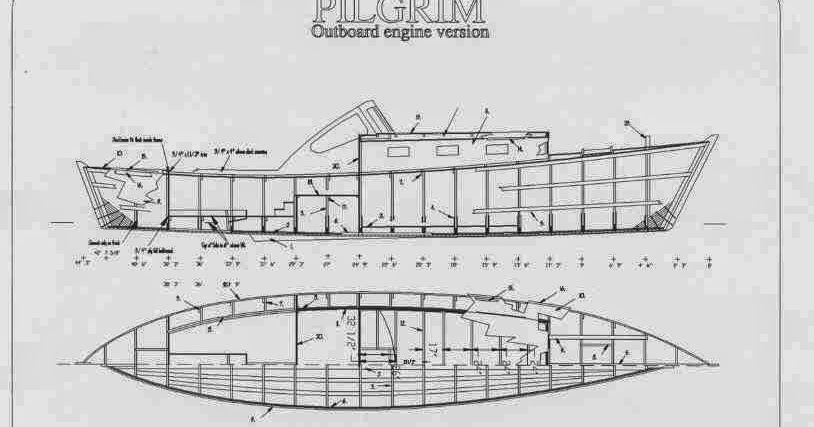

A: Careful planning is paramount. Use digital design software (e.g., SketchUp, Fusion 360) to create precise cutting plans, minimizing material waste. Furthermore, consider employing techniques like "scarfing" or "splicing" to join shorter pieces of lumber effectively, avoiding large cuts from valuable timber. Document your process meticulously; detailed plans for future projects will be invaluable â€" plus, you can share your knowledge with others! (Data from the Waste Reduction Alliance shows that strategic planning can drastically reduce material waste in construction projects.)

Beyond the Blueprint: Embracing Imperfection and Innovation

Wooden boatbuilding isn't just about following plans; it's about adaptation and ingenuity.

Q: How can I infuse my personal style and creativity into a traditionally designed boat?

A: The beauty of wooden boatbuilding is its inherent customizability. Don't be afraid to deviate from the original plans! Consider incorporating unique details â€" inlays of contrasting wood, personalized carvings, or even unusual paint schemes. Think about the overall aesthetic you want to achieve. Research historic boat designs from different cultures for inspiration; this provides a vast and untapped resource for stylistic innovation. Explore alternative fastening methods â€" traditional wooden pegs can offer a unique look and feel. The process becomes a unique reflection of your skill and vision.

Q: How can I troubleshoot unexpected challenges during the build process?

A: Every build encounters unforeseen obstacles. Instead of seeing these as setbacks, frame them as learning opportunities. Embrace problem-solving; utilize online forums and communities (such as those found on Reddit or dedicated woodworking websites) for advice and collaborative solutions. Document these challenges and their resolutions; this creates a valuable knowledge base for yourself and future boatbuilders. This type of experience-based learning builds resilience and resourceful problem-solving skills.

The Enduring Legacy: Passing on the Craft

The joy of boatbuilding extends beyond the finished product. It's about preserving a traditional craft and sharing knowledge.

Story: I once met a seasoned boatbuilder who started teaching at a local community college, passing on his expertise to a new generation. His students, many without prior woodworking experience, built functional and beautiful boats, forging lasting bonds through shared passion. This exemplifies the power of collaborative learning and the importance of mentoring in preserving traditional craftsmanship. Educational institutions can use books like How to Make a Wooden Boat as a starting point, building engaging curricula that combine hands-on experience with historical and environmental contexts.

In conclusion, How to Make a Wooden Boat for Fun and Outdoor Adventures serves as a springboard. By embracing sustainable practices, fostering creativity, and actively engaging in problem-solving and knowledge sharing, we can elevate the boatbuilding experience to a richer and more meaningful journey. This approach empowers individuals, strengthens communities, and ensures the enduring legacy of this remarkable craft.